Advances in Cold Press Juicing Equipment Produce Unforeseen Yields

by Polina

Industry professionals know that cold press juicing machines are the best way to get the purest, rawest and most nutrient rich juice for juice bars, health food stores, juice cleansing facilities and other small to medium juicing operations. However, without certain key technologies cold press juicers risk losing yield every cycle.

Industry professionals know that cold press juicing machines are the best way to get the purest, rawest and most nutrient rich juice for juice bars, health food stores, juice cleansing facilities and other small to medium juicing operations. However, without certain key technologies cold press juicers risk losing yield every cycle.

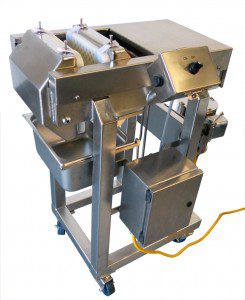

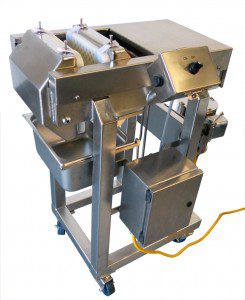

Modern juicing technology including “Thin Film Pressing” and “Wavy Press Boards” which are included in the Freshly Squeezed FS series of cold press juicers (FS-12, FS-20 plus, FS-30, F-60, and FS-120) are helping the juicing industry get the most out of their juice.

Andrew Grossman, Sales Representative for Freshly Squeezed LLC explains: “The cake releases its contents in this order: water, color, and flavor. The interlocking wave boards and Thin-Film pressing ensure not just the best yield, but also achieve the flavor profiles needed for high-end juice.”

These technologies are explained further below.

Thin Film Pressing:

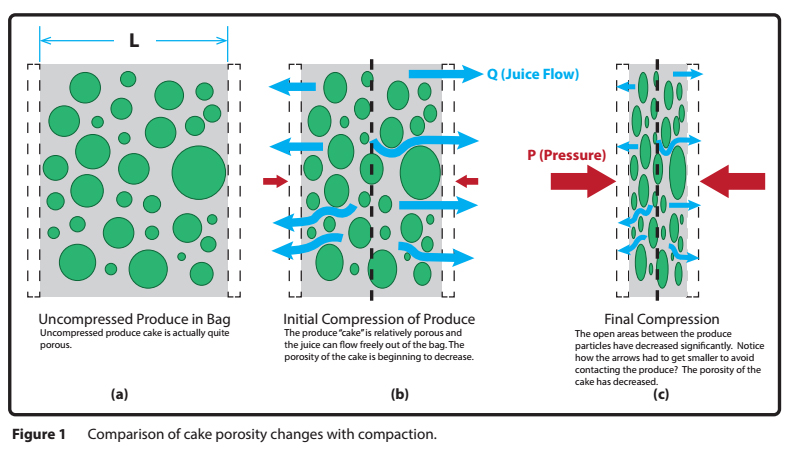

All cold pressed juicers use a cake pressure filtration system. One of the most important factors in juice production is cake thickness. More cake thickness = less juice flow = less bang for the buck.

This is where thin film pressing comes into play. By putting less produce in the filtration bag, cake thickness decreases, leading to more juice in less time and a greater ROI.

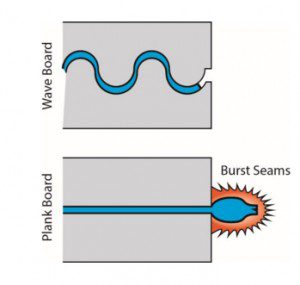

Wavy boards are an upgrade over the standard “plank boards” by supplying a larger surface area. This serves two functions:

• Better Distribution of Force. This helps ensure that the produce is distributed in a single direction in the bag (up or down instead of side to side).

• Bags “tuck in” to the board. This minimizes the amount the bag overhangs on the board. Overhangs trap produce outside the press area, which leads to over-pressure at the seams and bursting bags.